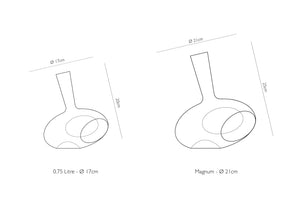

13˚ 60˚ 104˚ decanter (75 centilitres) Ø 17cm

£460

-

13˚ 60˚ 104˚

Borosilicate.

20cm tall, 17cm diameter.

Winner of the RedDot Design Award.Mouthblown in editions of twenty. Numbers 117 and 118 are available in the clear.

Yellow limited edition of fourty. One of three studio development samples available.

Some say that in the upright position at 13 degrees, the decanter starts the evening sober. As the night progresses, at 60 degrees, it is a bit tipsy. Later on the downward position at 104 degrees suggests that the decanter is ready for refilling.Decanters are mouthblown in Slovenia without using a mould. They are produced in batches of twenty, less than once a year. Each piece is engraved in Mayfair, London, with its unique number and comes with a certificate of origin (please email us to specify how the owner's name will be written). The decanter is protected by wood chips and shipped in a wooden wine box. To personalise, please see our engraving service here.

Designed to be practical, compact and lightweight, the 75 centilitre decanter fits the hand easily; for a larger format please see the magnum.

As seen in The Times LUXX, the Financial Times How to Spend It, The Sunday Times Style Magazine, Nowness, the Independent and Damn magazine. -

CLEANING

Clean soon after use with warm water. Towel dry and let any remaining water inside drain, by placing upside down, safely in a corner or in the top of a flower vase. For more stubborn deposits, we recommend the use of decanter cleaning balls. More detail about cleaning glass here, care of Daniel Primack. -

BOROSILICATE GLASS

A highly skilled lamp worker mouth blows decanters on a lathe. The same processes is used to blow some scientific laboratory glassware.

Borosilicate is highly resistant to thermal shock as compared with other glass. It is sometimes described as 'hard glass' and melts at around 1650 degrees Celsius. Photographs of our borosilicate being formed may be seen here. -

EXPOSE TO AIR

As wine ages, it changes and gains complexity. However the full potential of its flavour is not always experienced.

Wine flavour develops most rapidly when the cork is removed and air makes contact with its surface. However, sadly, the rate of drinking often exceeds the rate of flavour transformation and the bottle finds itself empty before the wine has reached its peak. Happily, decanting increases the contact of air to the wine, which gives it a fighting chance against the enthusiastic drinker of reaching its full potential. It is desirable to pour wine into the decanter so that the it runs down the inside of the neck (rather than falling directly down the middle without contacting the glass). Using this method, when the wine reaches the spot where the body of the decanter meets the neck, it flows across the decanter wall in a thin sheet exposing the entire liquid to air allowing it to aerate beautifully.

"A genuinely pioneering product. This has, rather amusingly, turned decanting design on its head – or, to be precise, its side... Moreover, moving the decanter into each position increases the wine’s exposure to oxygen, thereby bringing out the flavours and aromas at a faster rate."

John Stimpfig - contributing editor at the Financial Times’ 'How to Spend It' & editorial content director of Decanter Magazine.

-

75 CENTILITRE or MAGNUM?

75 centilitre -

The 75 centilitre decanter will hold a regular size of wine bottle and allow the wine the space it needs to breath. It is designed to be compact, lightweight and practical. It fits easily into the hand (locate the thumb inside the 'punt' at the bottom of the decanter). Please study the measurements of each decanter in the drawing on this page. Whilst the 13˚ 60˚ 104˚ magnum also elegantly accommodates a 75 centilitre bottle, it makes a larger statement on the dining table.

Magnum -

The magnum decanter contains one and a half litres at 13˚ (the upright position), 750 millilitres at 60˚ and at 104˚ (the lowest position) a half bottle (375 millilitres). The magnum decanter also looks very happy holding the standard bottle in its upright position.

Both decanters are designed to be as compact as they can be, whilst still allowing optimum performance. Were the diameter to be reduced, air would be trapped when the decanter holds the full bottle of its intended format, causing a glug during the first pour, which is characterful for a wine bottle, but inelegant for a decanter.

White wine decanters photographed by John R Ward.

Wine consultant: Arno Maasdorp of the Saltoun Supper Club.

UK Design Number: 90021485100001

OHIM Design Registration number: 002148510-0001

USA Design Patent number: US D727,670 S

China Design Patent number: ZL 2013 3 0120618.8

Hong Kong Design Registration Number: 1200863.3